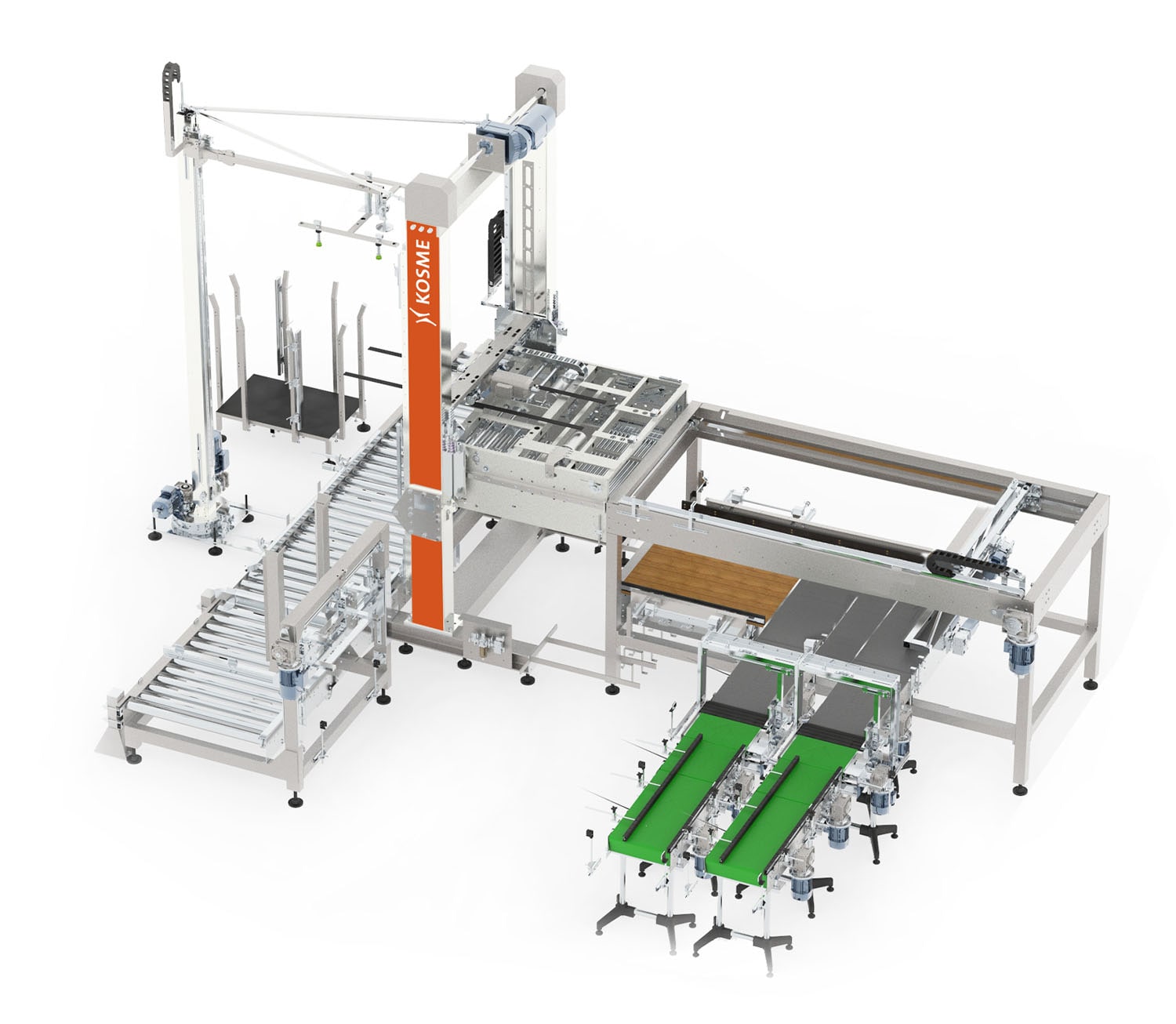

Automatic double column machine specific for high productions suitable for palletizing layers of cartons, plastic crates or other types of packaging. The product is arranged and ordered as per the pre-set scheme, in a grouping station with double infeed, before being pushed inside the gripping head; this then picks up the layer, compacts it and deposits it on the pallet. The machine is also equipped with pallet handling devices. The machine can be equipped with one or more pad dispensing devices for the automatic insertion of the interlayers between the layers.

Parcel entrance consisting of:

- spacer conveyor;

- double Pack turning device;

- double Gapper conveyor;

- Double row pre-formation conveyor;

- Layer formation plan

- 2G pusher;

Main machine components and options

- Automatic pallet storage warehouse;

- Motorized pallet conveyors to allow continuous operation of the machine;

- Electrical cabinet

- Pulpit with touch-screen control panel;

- Perimeter safety protections with mesh panels;

- Any access inside the working perimeter of the machine is allowed only through doors with micro-interlocked or if open, is controlled by photoelectric barriers

Optional:

- Automatic device for inserting flat interlayers;

- Interlayer storage warehouse;