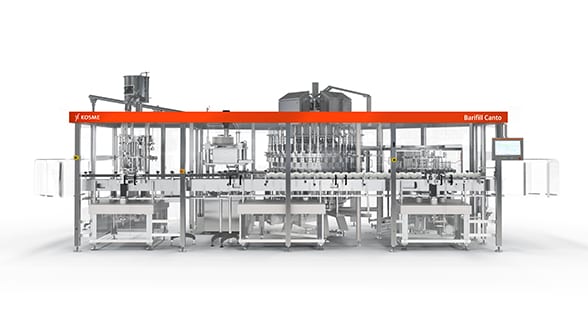

Weighfill - Filling machine for corrosive product

The Filler and Capper has been made in corrosion-proof version to fill Clorine in high concentration.

Filling Valves and parts in direct contact with the product made with Corrosion-proof materials capper and Trigger/Pumps inserting mainly made with parts in Titanium or Hastelloy C or PVC or PP or PE or Halar but also with others materials that Kosme R&D evaluate product by product.

All the machine points where there are space inside are pressurized in order to avoid GAS infiltrations.

- High precision filling

- Ability to perform two-stage filling (fine/gross flow)

- Fully sealed, fluid-proof digital load cell

- Versatile valve that meets all needs

- Tank washing using spray balls

- Modular base available to guarantee better shipment, installation, maintenance and cleaning

- Anti-corrosion treatment on each component