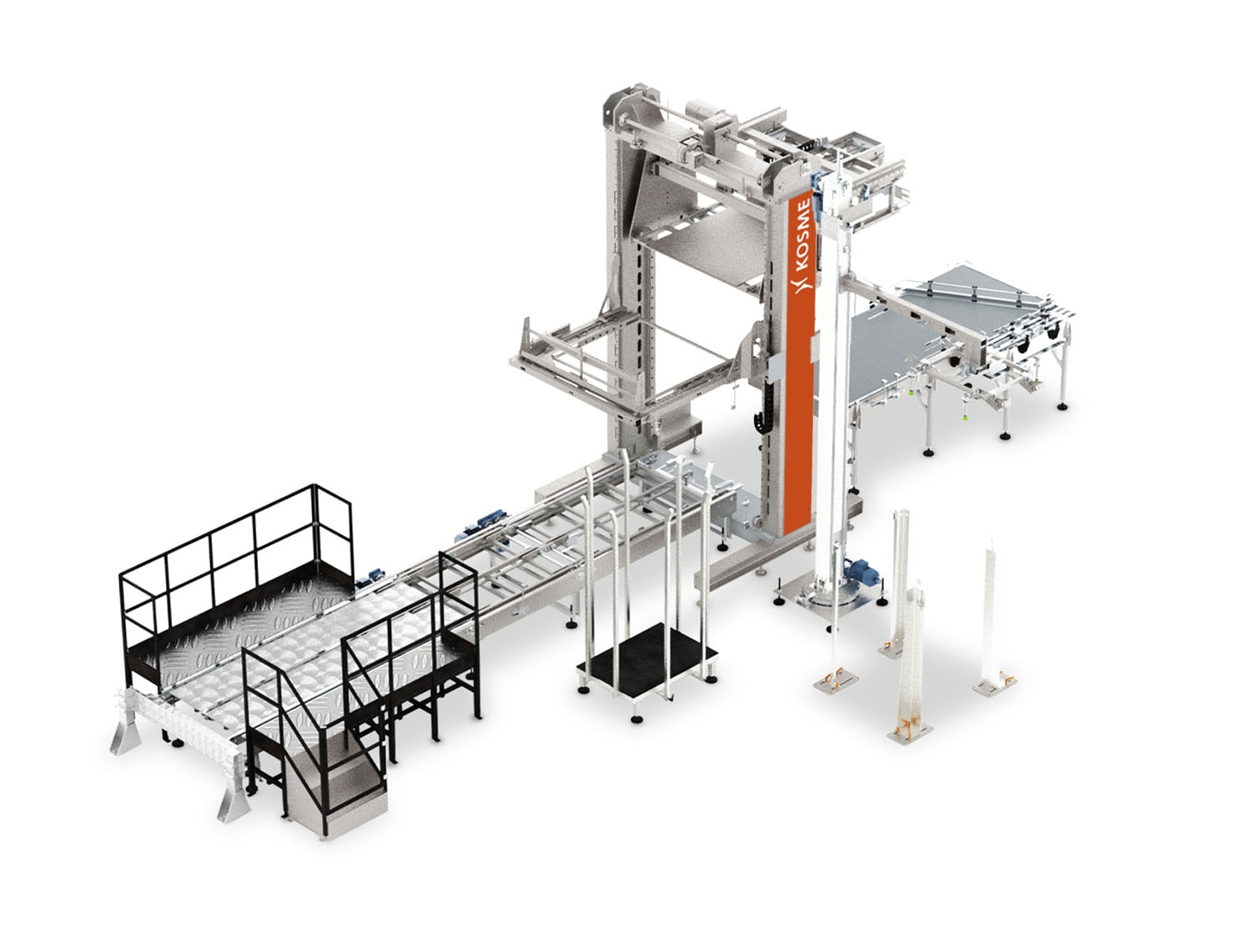

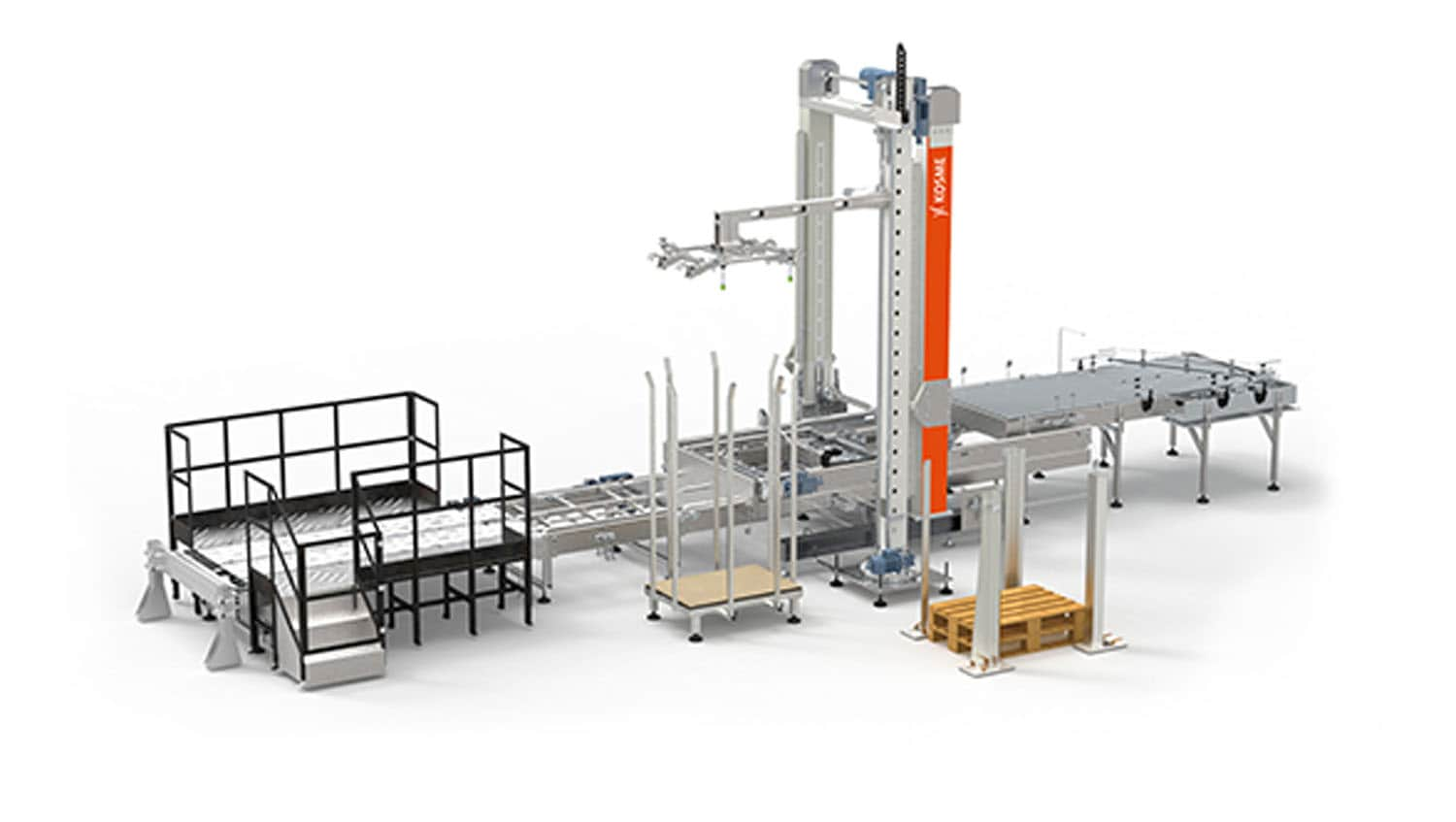

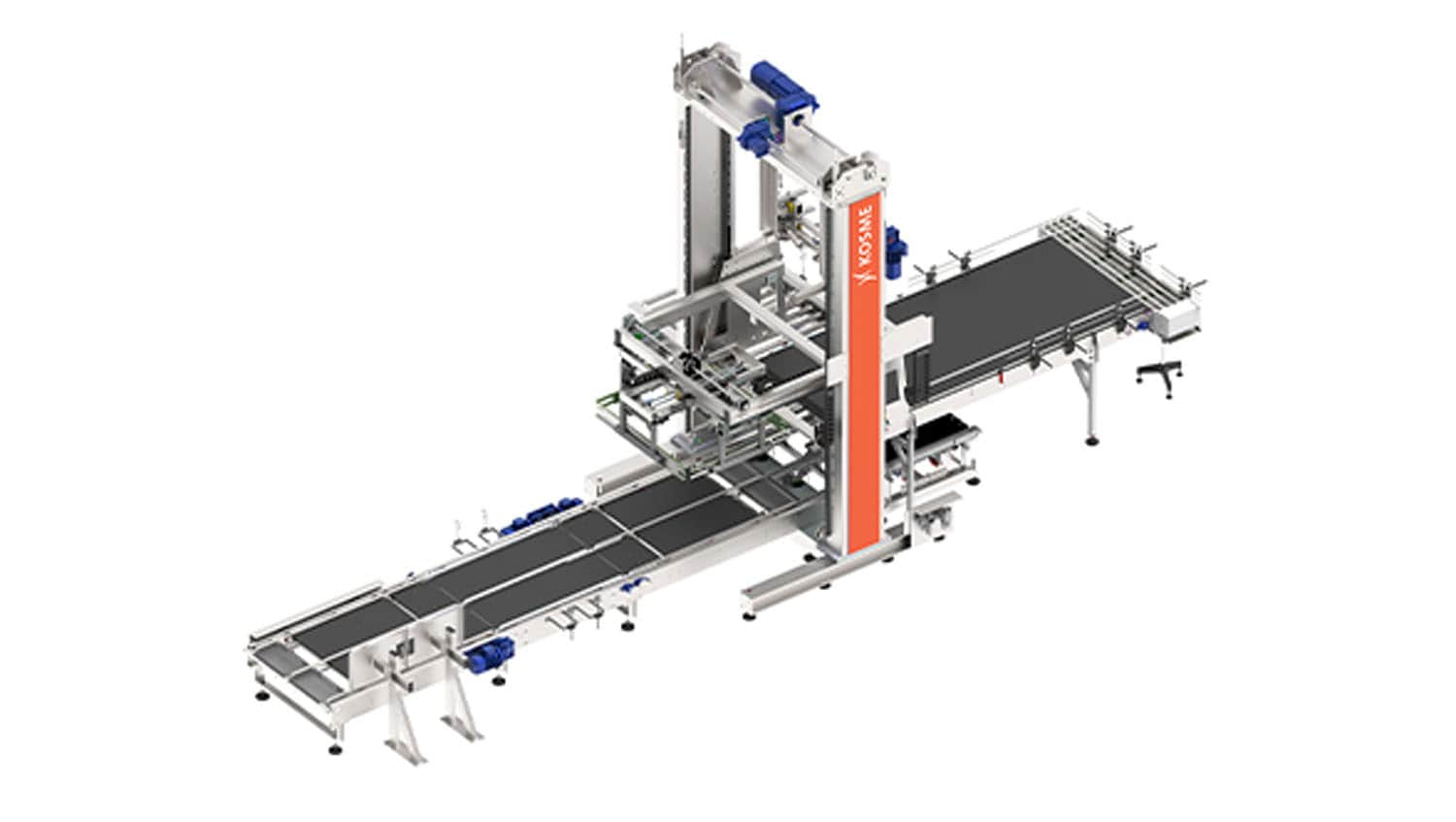

Automatic double column machine with layer stabilization device independent from the carriage specific for high production, depalletizes containers or crates and removes flat and / or inverted tray interlayer. The depalletising is performed with a sliding system of the complete layer on the container unloading table, which is equipped with a multi-row outlet. The machine is also equipped with an extractor for automatic removal and handling of layer pads and pallets. For their storage, the appropriate warehouses are available.

Main machine components and options:

- Multidepal (depalletizing machine with 26sec cycle time)

- Layer retention device independent from the machine carriage

- Container unloading bench with multi-line outfeed

- Robot for the removal of layer pads and pallets

- Interlayer storage warehouse

- Empty pallet storage warehouse

- Motorized pallet conveyors to allow continuous operation of the machine

- Area dedicated to the undressing of pallets with appropriate stairs and walkways

- Electrical cabinet

- Pulpit with touch-screen control panel

- Perimeter safety protections with mesh panels

- Any access inside the working perimeter of the machine is allowed only through doors with micro-interlocked or if open, is controlled by photoelectric barriers

Optional:

- Storage warehouse for top cover